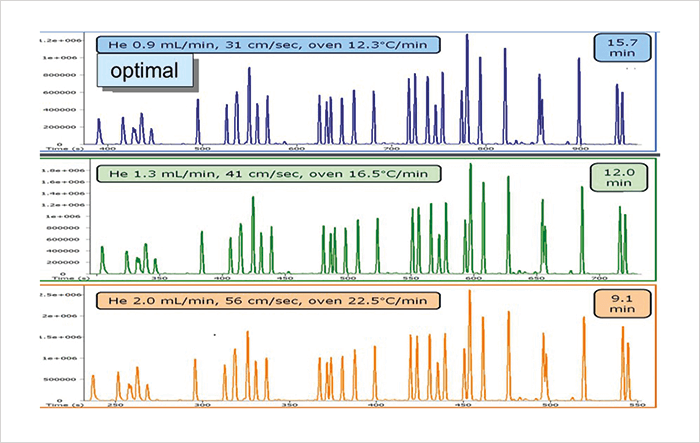

Reducing analysis time is a constant priority. And it’s sensible because it cuts costs per analysis and you get faster results. Here, I’d like to share some clever ways to reduce gas chromatography (GC) analysis time using existing instrumentation in two real-world situations. Chromatogram peaks are well separated – we can shorten time of analysis by trading some efficiency through following these steps. i) Use the column flow for higher velocity separations. Surprisingly, not many people use this powerful option, and yet you can use it immediately because all GC systems are equipped with electronic flow/pressure/gas-velocity controls. By separating at a higher gas velocity, it is possible to reduce the analysis time by a factor of 2–5. The system is not optimal with respect to plates, but because we have sufficient resolution, we can trade plates for time (see Figure 1). The additional advantage is that the fastest eluting peaks will be higher than the rest. If you do not want to change the injection conditions that you were/are already using, you can program the higher velocity injection to start after the first injection is complete. It is very important that when linear velocity or column dimensions are changed, you also adjust the oven temperature to make sure that the components elute at the same temperature; if the elution temperatures are the same, the exact same chromatogram is obtained. To calculate the oven temperature program, you can utilize free software available as a web- or Windows application (1).

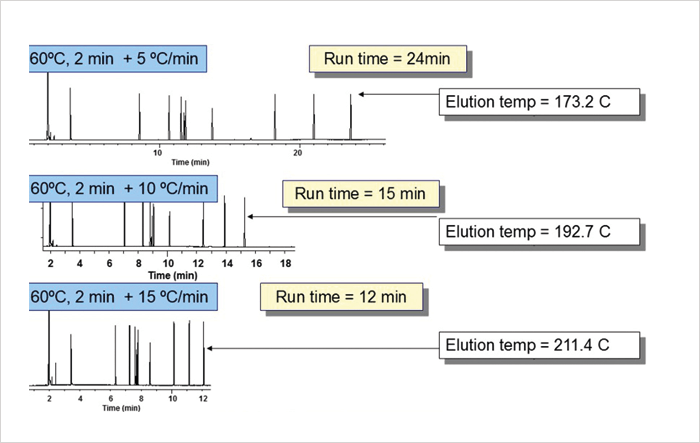

ii) Use a different temperature program. By using a faster program rate, peaks will elute sooner and at higher intensity (see Figure 2). Elution temperatures of components will change, which may result in a different separations. For very fast programs, you can use an “oven-pillow” to reduce the oven size. iii) Use a shorter column. Shorter columns elute peaks faster but only reduce separation ever so slightly. My thinking is: “the better the chromatographer, the shorter the column”. If you opt for this approach remember to adjust the temperature program using method translation to get the same chromatogram – you can use the free software again for this (1). Note that using a system with less efficiency (plates), also means that peaks will run faster into each other during column ageing. The implication is that you’ll need more column maintenance and the lifetime of the equipment is shortened. But that’s the price you pay for faster results!

Existing peaks are just separated, and you don’t want to reduce efficiency.

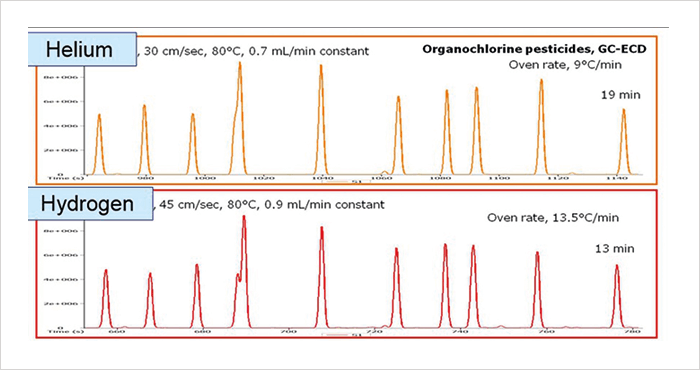

iv) Use a faster carrier gas. Hydrogen has about 50 percent higher optimal linear velocity compared with helium, which enables significantly faster separations while efficiency remains comparable (see Figure 3). As the linear velocity is changing, to get a similar chromatogram you have to adjust oven temperature using method translation (1). The great thing about hydrogen is that it is relatively cheap and you can make it in the laboratory using a generator. A potential downside with hydrogen is safety, but you can reduce the risk of hydrogen release by using hydrogen sensors in the oven, flow controlled systems, or metal (MXT) capillary columns. You can also use hydrogen with mass spectrometry (MS) systems, but there are some anomalies. Polar compound spectra may show +1 m/z fragmentation and the ion source can display some initial activity. And, when existing systems are converted to hydrogen, you may see some hydrocarbon background that can last for several days. Oils extracted from the “O” rings used in electronic pressure control systems cause this unwanted effect...

v) Use a smaller diameter capillary. Replacing a 30 m × 0.25-mm capillary with a 20 m × 0.15- mm capillary with the same phase ratio shortens run times by a factor of 2 but maintains efficiency while using the same carrier gas. Because the eluting peaks are narrower, you can reduce the amount of sample injected to generate the same signal. For a long time, we’ve known that 0.15-mm ID columns work well and they can be used in any type of GC or GC-MS system. They are available with different phase technologies and they are easy to install, as the OD is the same as a 0.25-mm capillary, so you can use the same ferrules.

For maximum impact, you can combine all these tactics to get the shortest possible analysis time!

For an extended discussion of all these options, see my blog (2).

References

- EZGC Method Translator and Flow Calculator. http://www.restek.com/ezgc-mtfc J de Zeeuw, “Fast(er) GC: How to decrease analysis time using existing instrumentation? Part III: Impact of using faster temperature programming”, Chromablography, August 10 (2011). http://blog.restek.com/?p=3414