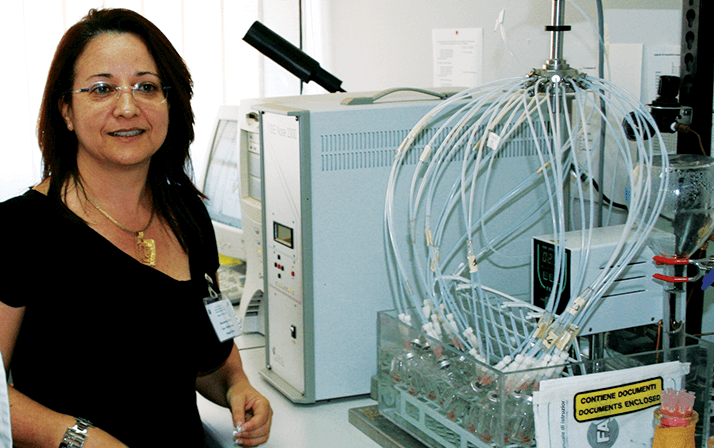

The prevention of deceptive, fraudulent, or downright dangerous practices is a constant and major challenge facing the food industry. Now, a team from the Laboratory of Food Chemistry at the University of Reggio Calabria led by the (appropriately named) Mariateresa Russo has unveiled a new E-Nose system and data analysis approach that could strengthen the field’s defensive armory (1). The product under analysis? Not red wine, for which Italy is rightly famed, but red onions.

“The Cipolla Rossa di Tropea [red onion of Tropea], produced in the Italian region of Calabria, has been recognized by the EU Protected Geographical Indication thanks to its unusually sweet aroma and low level of pungency – and hence its quality,” explains Russo. Like many other goods covered by specific European protection, the cyanidin-rich bulbs prove too tempting to counterfeiters. “The implementation of simple, affordable, power efficient, reliable, and sensitive devices for real-time analysis is a current priority for food quality and authentication,” Russo says. While some research groups are attempting to convert advances in microtechnology into viable miniaturized gas chromatographs and mass spectrometers, Russo and colleagues believe that nature offers a more affordable template: “the alternative is a biology-inspired approach where gas composition is recognized as an odor ‘fingerprint’ or ‘pattern’ rather than as a set of spectral features.” A typical E-Nose system mimics the mammalian olfactory system with an array of partially specific artificial electrical ‘receptors’ – 12 metal oxide semiconductor sensors in this particular case – coupled with pattern recognition techniques to process the signals. “It doesn’t decompose the aroma fraction of the matrix into its constitutive components,” says Russo, “rather, it supplies a global evaluation of the aroma in an attempt to provide objectivity”.

As with any system of this nature, it is perhaps the data analysis that provides the biggest challenge. The team used Discriminant Function Analysis (DFA) to convert the large amounts of information generated by the sensors. “DFA transforms data using linear discriminant functions (LDFs) in a similar manner to PCA. However, where PCA attempts to maximize all variances present in the data, DFA generates an LDF to maximize the distance between two given centroids within the data, taking the variances of the two groups into account,” says Russo. “So, where PCA could be seen as part of an unsupervised classification system and is used to explore the data and to assess discrimination performance, DFA forms part of a supervised classification system – groups must be known a priori to perform DFA.” In other words, DFA is used to categorize unknown samples into one of several already known groups. Russo’s approach yielded an impressive 97.5 percent correct classification rate (CR) overall. “The discrimination is considered ‘excellent’ if the percentage of recognition is higher than 90%. The DFA of our onion samples showed a clear separation among the four onion groups assessed. Such a high recognition rate confirms our hypothesis based on results from classical analytical techniques, which demonstrated clear qualitative differences between the types of onions compared.” Whether the approach can be considered truly non-destructive, as the title of the paper suggests, is up for debate; the onion’s edible parts were homogenised and filtered before the addition of 5 percent trichloroacetic acid to terminate allinase activity. It is not reported how good the red onion marmalade tasted after that…

References

- M. Russo et al., “Non-destructive flavour evaluation of red onion (Allium cepa L.) Ecotypes: An electronic-nose-based approach”, Food Chemistry 141, 896–899 (2013).