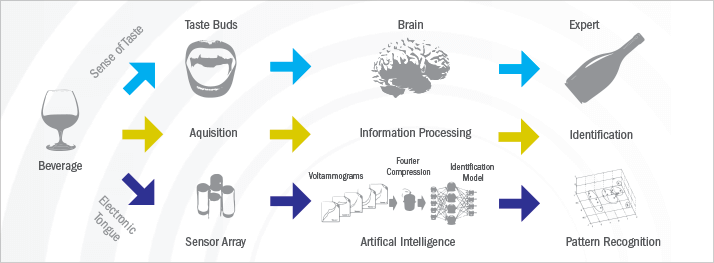

The Analytical Scientist spoke with Manel del Valle from the Sensors and Biosensors Group at the Universitat Autònoma de Barcelona. His system combines a voltametric electronic tongue with an artificial neural network model trained for the semi-quantitative identification of several undesired compounds that indicate brandy defects.

How is the voltametric array constructed?

Carbon electrodes are combined with chemical compounds, such as nanoparticles, conducting polymers, and certain redox catalysts, at around 5% proportion to the initial mixture to form “modified epoxy graphite composite electrodes”.

Similar sensor arrays have already been successfully applied to wine characterization and beer evaluation. In the case of brandy, undesired compound markers include: butan-2-ol, ethyl acetate, acetaldehyde and butan-1-ol. We also quantify the polyphenol index.

And how is the signal from the array processed?

The data generated per sample are highly complex, featuring three components: current, polarization potential and sensor type. They undergo Fourier transform, much like the compression of a CD audio file into an mp3 file, in which a reduced number of Fourier coefficients per voltammogram are stored. High frequency components are discarded as noise. The Fourier coefficients are then analyzed using pattern recognition methods, including Fisher’s Discriminant analysis for sample classification and identification, and an artificial neural network.

How does this relate back to the quality of the liquor?

A large number of samples previously processed by a human sensory panel have been translated into the artificial intelligence (AI) model. Cross-validation of the model with a second set of samples not used in the training of the system confirmed that we could correctly classify brandy samples.

Are there limitations to this type of system?

Not all quality factors in the food/beverage industry are easily tackled with E-noses or E-tongues, for example, the spoilage of wine corks by trichloroanisole (TCA), a metabolite of residual fungi in the cork. Human senses are extremely sensitive to TCA, an anomaly that makes for an extremely demanding application. The problem is caused by the lack of sufficiently sensitive sensors for this compound.

Drift is also an issue, in which sensors can alter in behavior, invalidating the generated model.

What are other possible for uses the E-tongue?

One obvious area is in environmental applications where continuous unattended monitoring of complex processes is required. In any use of E-Senses, shifting the complexity of the analysis from the measurement to the data treatment, a feature made cheaper every year, will be a key driver.